Professional Work Gloves for Industrial Safety

Our safety work gloves are designed to protect workers' hands from different hazards including chemical exposure, abrasions, cuts, burns, electrical risks, punctures, and various other dangers on the job.

Categories of Our Work Gloves

We provide three main categories of work gloves, each designed for specific applications and protection requirements.

NR LATEX (base) COATED GLOVES

Natural Latex (NR Latex) is a processed leachate of the Hevea tree (rubber tree) that can be grown in tropical forests such as Southeast Asia, South America, South Africa.

Key Features:

- High tensile strength and vibration damping properties

- Good electrical insulation

- Resistance to most mineral acids, salts and alkalis

- Ideal for general use and mechanical hazards

- Superior cut resistance performance

NBR (Nitrile base) Coated Gloves

Nitrile rubber, also known as nitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene.

Key Features:

- Stable at temperatures from −40 to 108 °C (−40 to 226 °F)

- More resistant than natural rubber to oils and acids

- Superior puncture resistance

- Less likely to cause allergic reactions

- Ideal for aeronautical and chemical applications

Coated Gloves Based on Advanced Yarns

High-strength synthetic yarns such as para-aramid (Kevlar) and high-performance polyethylene (HPPE) provide exceptional cut resistance level 5 and above.

Key Features:

- Kevlar fibers: 5 times stronger than steel

- HPPE: 8 times strength-to-weight ratio of high-strength steels

- Maintains flexibility at extreme temperatures

- Highest impact strength of any thermoplastic

- Ideal for maximum cut protection

Natural Latex (NR) Technology

Natural rubber is superior to synthetic rubber due to its high tensile strength and vibration damping properties. Their excellent electrical insulation and resistance to most mineral acids, salts and alkalis make them ideal for general use applications.

Important Considerations:

- • Little resistance to petroleum solvents (oil, gasoline, naphtha)

- • Loss of strength at temperatures above 80°C

- • Quick deterioration in direct sunlight without special compounds

Nitrile (NBR) Technology

Nitrile rubber's stability at high temperatures from −40 to 108°C makes it an ideal material for aeronautical applications. Its resilience makes NBR useful for disposable lab, cleaning, and examination gloves.

Advantages:

- • More resistant to oils and acids than natural rubber

- • Superior puncture resistance

- • Less likely to cause allergic reactions

- • Excellent for chemical handling

Advanced Yarn Technology

Kevlar® (Para-Aramid)

Kevlar fibers are composed of long chains of Polyparaffinol Terephthalamide, making the inter-chain bonds extremely strong.

- Strength 5 times greater than steel

- Maintains strength and flexibility down to -196°C

- Slightly stronger at low temperatures

- 10-20% strength decrease above 160°C

HPPE (UHMWPE)

Ultra-high-molecular-weight polyethylene is a subset of thermoplastic polyethylene with extremely long chains and high molecular mass.

- Strength-to-weight ratio 8 times that of high-strength steel

- Highest impact strength of any thermoplastic

- Not advisable above 80-100°C for long periods

- Becomes brittle below -150°C

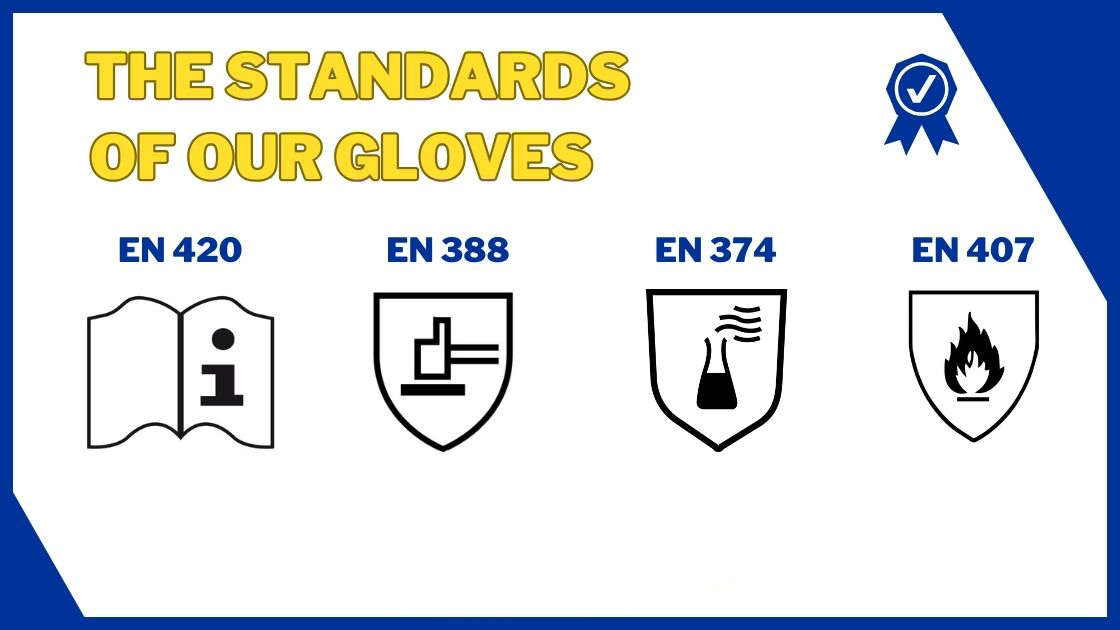

EN Standards Compliance

If a protective safety glove is deemed to meet the safety requirements and is given a CE mark in EU countries, it can be exported and sold throughout the EU zone. Our gloves comply with the following EN standards:

Protective gloves – general requirements

Includes sizing and defines general and valid requirements for all protective gloves

Protection against mechanical risks

Requirements for safety gloves (Abrasion/Cut/Tear/Puncture)

Protection from thermal hazards

Requirements against flammability, radiant heat, contact heat, and molten metal splash

Protection against chemical hazards

Type A/B/C resistance to penetration of chemical materials

Protection from cold

Requirements for gloves providing cold protection

Manual metal welding protection

Specialized protection for welding operations

Anti-vibration gloves

Protection against vibration hazards

Protection against cuts and knife nicks

Specialized cut resistance requirements

Performance Standards

Minimum Level Required (MLR) for Type A and Type B safety gloves according to EN standards

| Standard | Test | Type A (MLR) | Type B (MLR) |

|---|---|---|---|

| EN388 | Abrasion | 2 | 1 |

| Cut | 1 | 1 | |

| Tear | 2 | 1 | |

| Puncture | 2 | 1 | |

| EN407 | Burning behaviour | 3 | 2 |

| Contact heat | 1 | 1 | |

| Convective heat | 2 | – | |

| Small splashes of molten metal | 3 | 2 | |

| EN420 | Dexterity | 1 | 4 |

*MLR: Minimum Level Required

Need More Information?

For more info do not hesitate to contact us 24/7. Our customer relation team will answer quickly with detailed specifications, pricing, and delivery options.